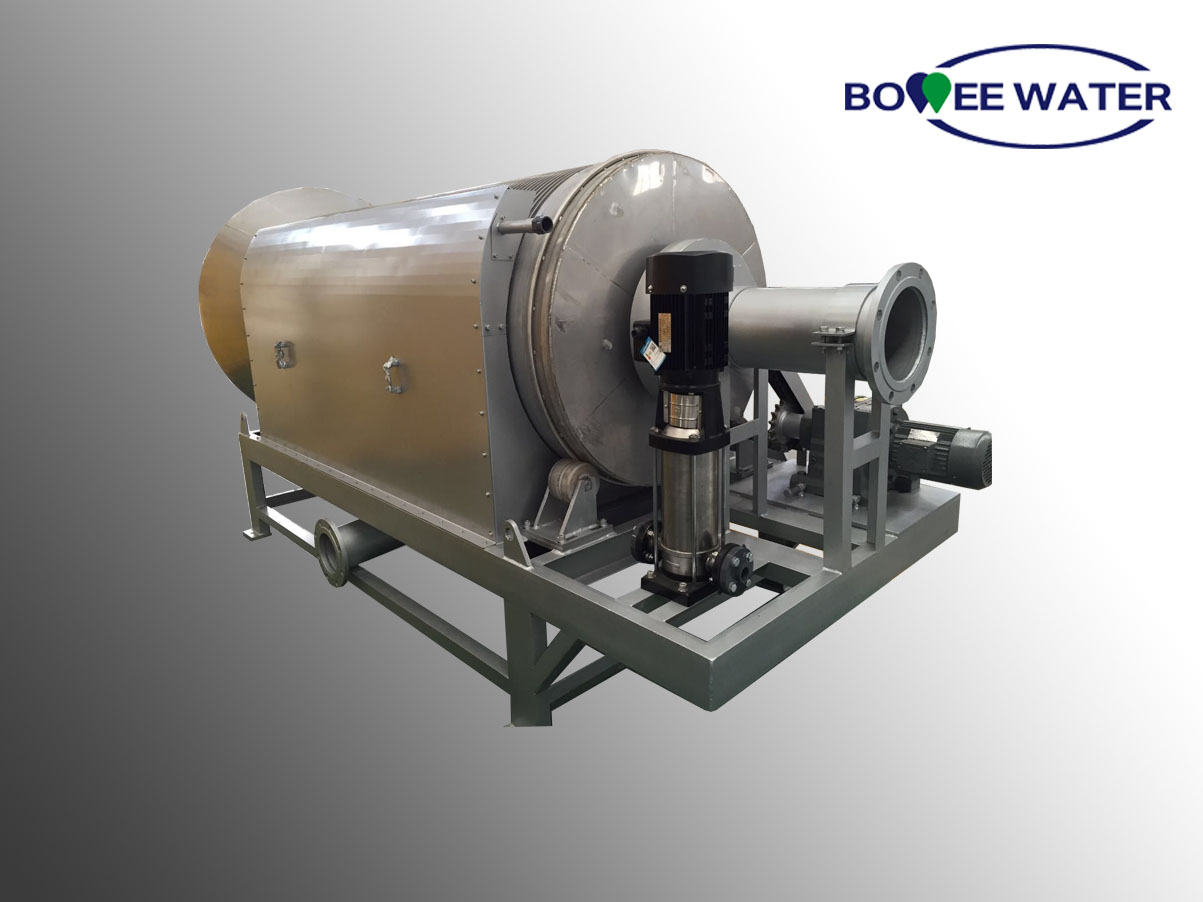

The Internal-feed Rotary Drum Screen is composed of a tank and a spiral connected to the drum for the transport of screening. The screen is composed of a perforated plate or wedge wire whose holes diameter is as big as the desired openings size.

Specifications:

Capacity: 0-750m3/h

Dimension: Customized

Material: SS304, SS316 or Customized

Opening type: wedge wire or perforated

Opening size:0.15-5mm

Motor brand: First-class motor, Nord or SEW is optional